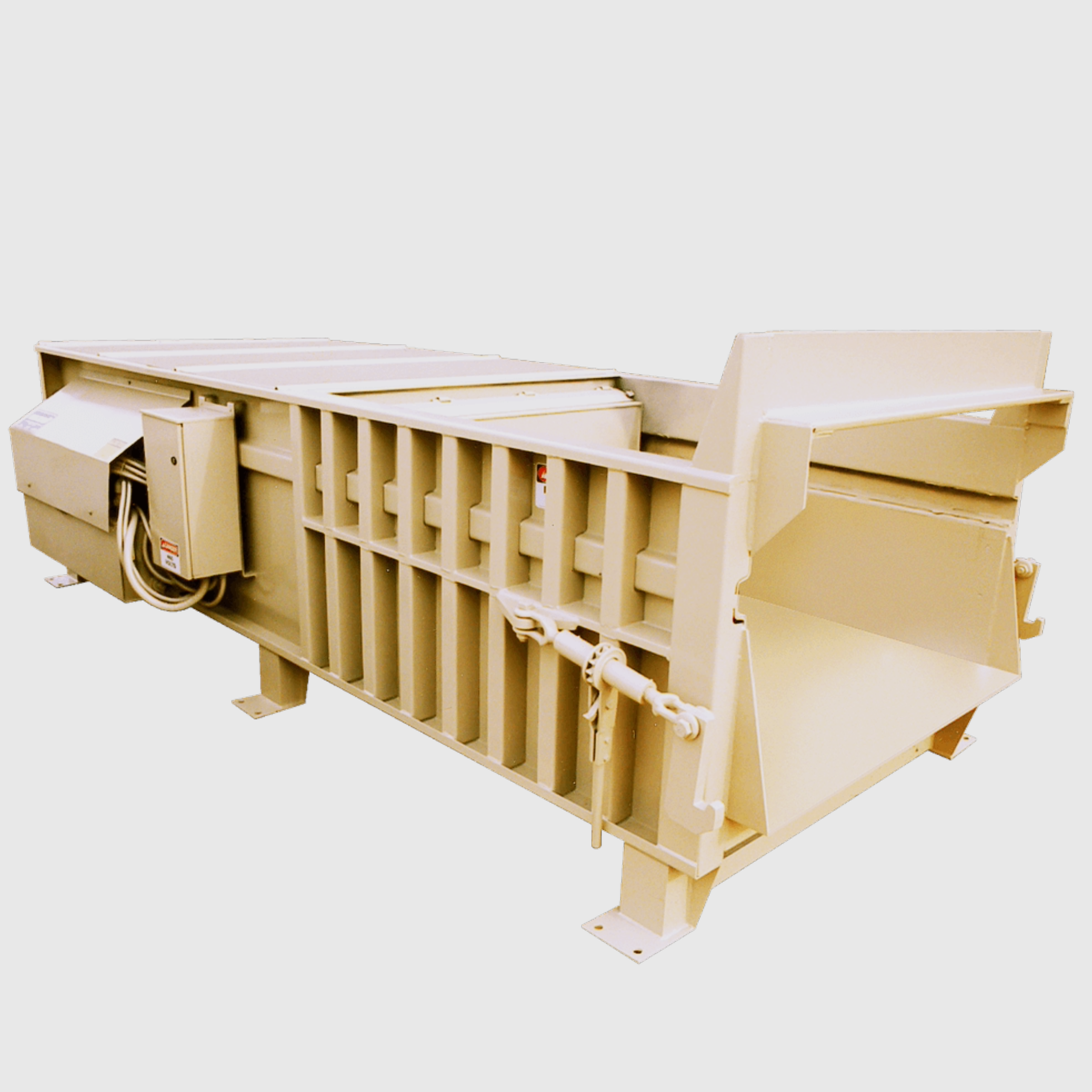

Stationary Compactors

Experience End2End’s efficient waste management with our stationary compactors, ideal for sites with substantial waste production. These systems compact waste directly where it’s generated, significantly reducing its volume and the need for frequent pickups. Our efficient stationary compactors are designed to minimize waste transportation costs and improve overall sustainability.

The fixed compactor and detachable containers facilitate uninterrupted and eco-friendly operation, helping reduce the amount of waste sent to landfills. With customizable options like secure chutes, walk-on or vehicle access decks, enclosures, multi-sided hoppers, and hydraulic cart dumpers, we provide automation solutions tailored to your specific waste management needs.

Also see our Efficient Compactors for Sustainable Waste Management

Proudly built in the USA, our compactors ensure quality and ease of maintenance by utilizing components from well-known brands. Our reliable stationary compactors help industries such as manufacturing, retail, and distribution centers improve waste efficiency and meet sustainability goals.

Fill in the Form Below to Find the Right Stationary Compactor for You

Find Your Stationary Compactor

Sustainable Waste Solutions with Stationary Compactors

End2End Logix understands that effective waste management is key to sustainability. Our efficient stationary compactors are designed to reduce the volume of waste, including cardboard, plastic, and other recyclables, while optimizing transport efficiency. By compacting waste into smaller, denser loads, businesses can significantly lower transportation costs and minimize their environmental footprint. Whether you’re in retail, warehousing, or industrial waste management, our compactors provide a solution that fits your needs.

Reliable Stationary Compactor Equipment for High-Volume Waste Management

A stationary compactor is an essential piece of recycling equipment for businesses managing large volumes of waste, especially in retail, warehouse, and manufacturing settings. Built to handle materials like cardboard, paper, plastic, and glass, these machines apply constant force to reduce trash volume by the cubic yard, helping streamline waste removal and improve operational efficiency. With robust steel construction, precision pressure control, and components like oil filters, hoses, and interlocks, each stationary compactor ensures consistent performance for industrial waste and packaging materials.

End2End’s commercial trash compactors are compatible with conveyor systems and dumpsters, offering versatility for distribution centers and property managers aiming to minimize landfill contributions and optimize sustainability practices. Our equipment supports liquids and scrap material containment with leak-resistant containers, odor control features, and optional oil heaters for cold environments. From voltage-matched pump systems to remote control operation and accessible service panels, our machines are designed to meet your site’s unique demands. Request a quote to see how our stationary solutions can enhance your waste management strategy.

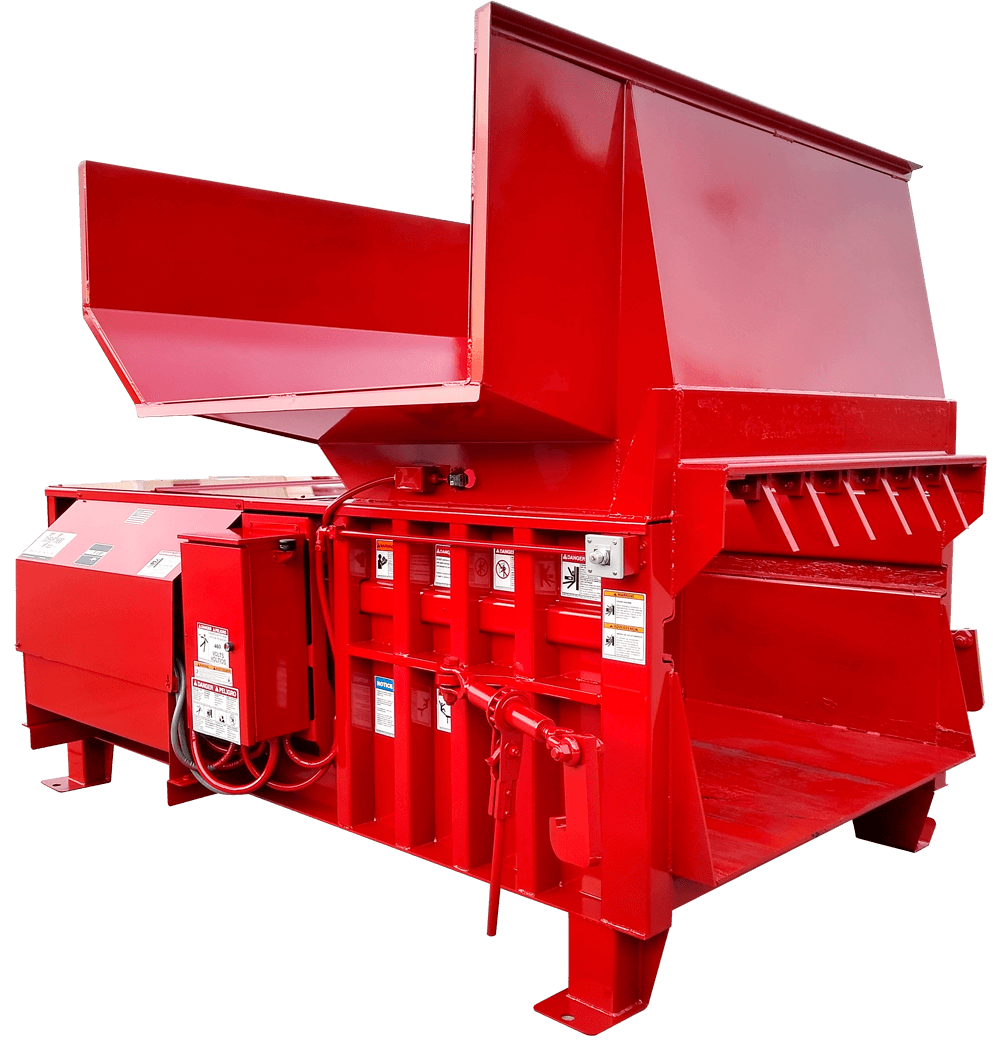

Integrated Stationary Compactors

End2End Logix’s integrated stationary compactors combine compaction, containment, and transfer functionality into one streamlined system—ideal for facilities prioritizing automation and throughput. These advanced units expand on our standard stationary compactors by embedding control technology and modular components that simplify waste handling in large-scale environments.

Engineered for minimal maintenance and consistent performance, each system supports continuous operation with features like synchronized loading interfaces, programmable compaction cycles, and optional hydraulic accessories for hands-free transfer. Their adaptable architecture allows seamless integration with existing material handling infrastructure, including balers, conveyors, and robotic case packers.

By consolidating the compaction process into a single operational flow, integrated systems eliminate bottlenecks and improve waste processing across high-volume zones. This approach not only reduces handling time and labor demands, but also enhances waste stream control—making it easier to align with recycling programs and corporate sustainability targets.