Vertical Balers

Efficient Vertical Balers for Sustainable Waste Management

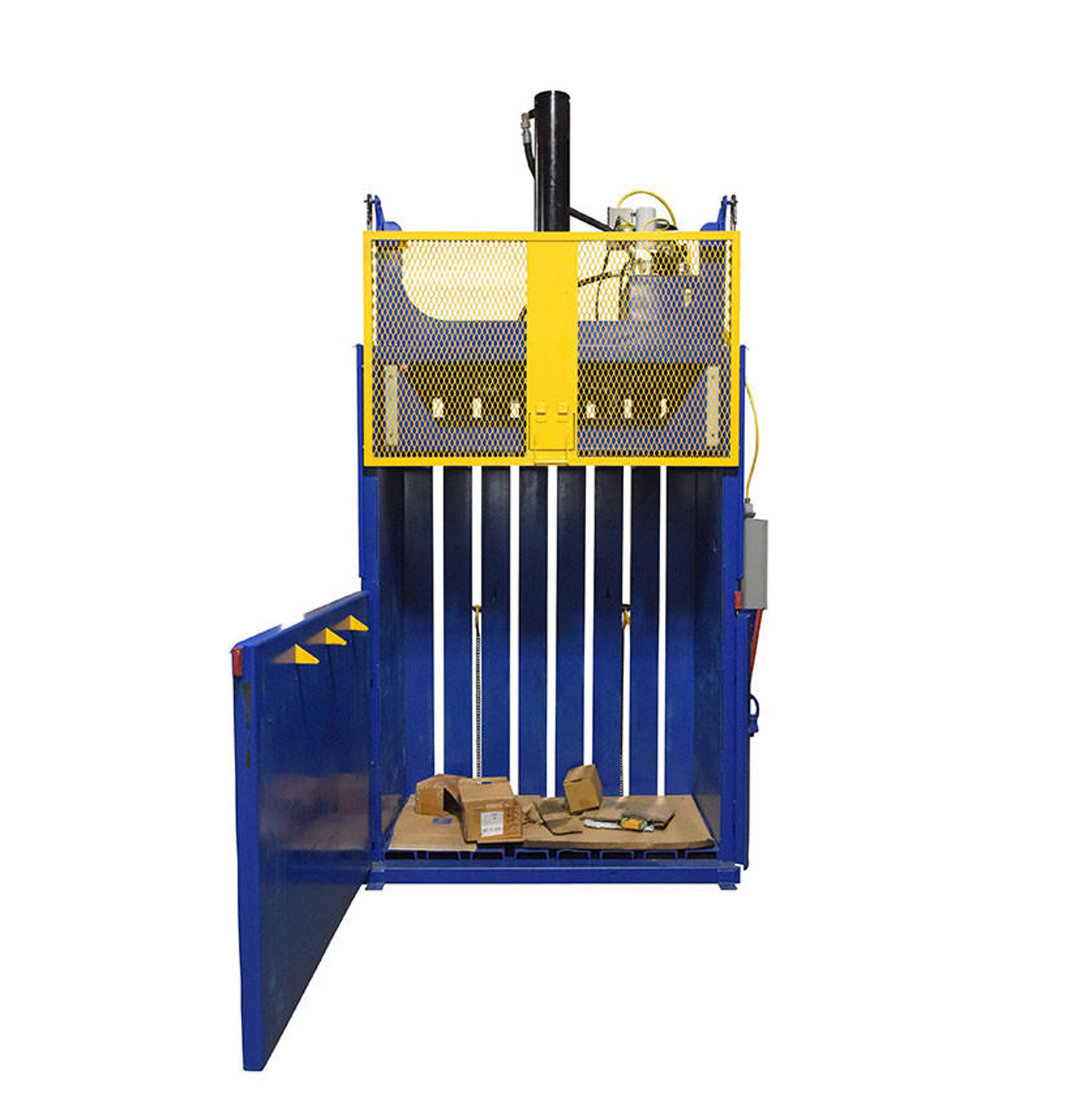

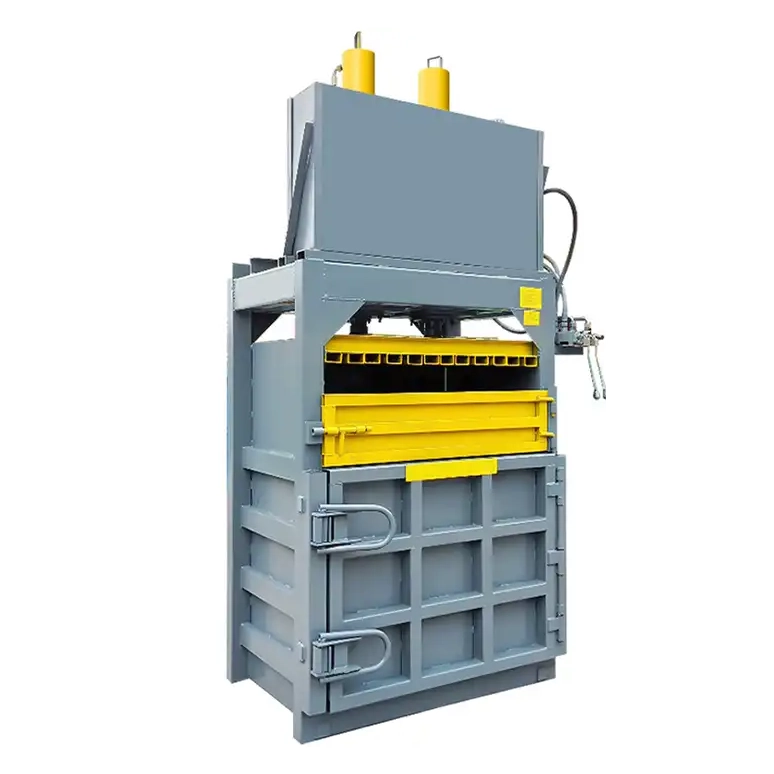

Transform your commercial waste management and recycling processes with End2End Logix’s state-of-the-art Vertical Balers. Engineered for efficiency and sustainability, these warehouse balers are the ultimate solution for minimizing waste volume and improving recycling efforts. Their space-saving design makes them ideal for versatile placement in retail stores, stockrooms, warehouses, and manufacturing facilities.

With exceptional compaction force, these balers effectively reduce the volume of recyclable materials such as cardboard, paper, plastics, and more, ultimately saving space and cutting disposal costs. Their user-friendly operation, customizable bale sizes, and low maintenance ensure a seamless baling process. Moreover, these balers contribute to environmentally responsible waste management by reducing your business’s carbon footprint.

also see our compactors for more waste management solutions

Prioritizing safety with integrated features, investing in our Vertical Balers will revolutionize your waste management, enhance efficiency, and promote sustainability, making them an ideal choice for commercial businesses.

Our warehouse balers are engineered to meet the demands of high-volume environments while ensuring compliance and improving workflow. From distribution centers to large-scale storage facilities, these balers streamline recycling by drastically reducing the volume of recyclable waste like cardboard and shrink wrap. This not only helps meet sustainability goals but also cuts back on the frequency and cost of waste removal services.

Equipped with advanced safety mechanisms and space-saving vertical configurations, our balers maximize available floor space and ensure safe operation for warehouse teams. By adopting warehouse balers into your operations, your facility can maintain regulatory compliance and contribute to corporate environmental responsibility initiatives—without compromising on performance.

Our vertical warehouse balers provide an efficient solution to minimize waste volume, specifically designed to handle the demands of high-traffic environments like stockrooms, warehouses, and distribution centers. By compacting cardboard, paper, plastics, and other recyclable materials, these balers save space and reduce the need for frequent pickups, lowering disposal costs. Integrating stockroom balers into your waste management system supports compliance with regulatory standards, such as those from the United States Environmental Protection Agency, while promoting sustainability and productivity.

Key Advantages for Warehouse Operations:

- Reduces greenhouse gas emissions by decreasing waste transportation

- Improves warehouse efficiency by maximizing available space

- Contributes to sustainable development goals and supports zero waste initiatives

- Helps streamline overall waste management processes, reducing costs and enhancing productivity

Key Features

Efficient Waste Compaction

With exceptional compaction force, our Waste Compactors effectively reduce the volume of recyclable materials such as cardboard, paper, plastics, and more, saving valuable space and cutting disposal costs.

User-Friendly Operation

Our Waste Compactors feature user-friendly controls and customizable compaction settings, ensuring a seamless compaction process and enhancing operational efficiency and productivity.

Low Maintenance:

Designed for reliability and longevity, our Waste Compactors require minimal maintenance, reducing downtime and ensuring continuous operation.

Space-Saving Design

Their compact footprint allows for versatile placement in various environments, maximizing floor space and optimizing workflow.

Ideal For

Retail Stores

Manage cardboard, paper, and plastics efficiently in retail environments.

Manufacturing Facilities

Streamline waste management processes in manufacturing plants.

Warehouses & Distribution Centers

Warehouses & Distribution Centers

Recycling Centers

Process recyclable materials effectively and contribute to a cleaner environment.